Geooblock: A System with Integrity

Geoblock®

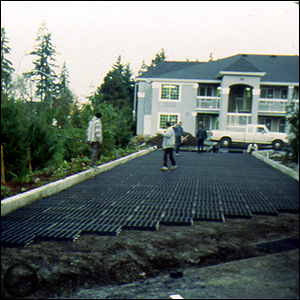

Standard 5150 (GB 5150) and the Geoblock® Porous Pavement Systems are a

series of interlocking, polyethylene paving units designed to provide

superior load support and turf protection for emergency and utility access

lanes, auxiliary parking, golf cart pathways, trails, and other high-use

application areas. The Geoblock® system provides vehicular and pedestrian

load support while protecting the grass from the harmful effects of traffic.

The Geoblock system covers a larger surface area per unit .5m x 1.0m x 50mm

(20" x 40" x 2 inch Nominal), reducing costs and increasing ease of

installation. The system's four-sided tabular, interlocking joint design

aids in pattern layout and transfers shear loads from block to block. While

some talk about strength per square foot, the structural integrity of the

Geoblock® system is built in. The system features a four-sided tabular,

interlocking block design that provides superior load-bearing performance

and performance and layout design and construction flexibility. The

recommended staggered placement (bricklayer’s pattern) of the individual

Geoblock units further increases the system’s load distribution capabilities

and maximizes the number of adjacent units used to effectively spread

concentrated wheel loads over the largest possible area.

Geoblock

& Geoblock5150 vs. Rolled Ring Competitors Product

Click here for GeoBlock component specifications and configuration examples.

See how Geoblock® can help you reach your US Green Building Council (USGBC) LEED Credits confirmation goals.

Geoblock

Applications

From fire access lanes to hiking

trails to ATV trails, parking areas, to golf cart paths, the Geoblock® system

improves both the usefulness and aesthetics of an outdoor environment:

Emergency and utility access lanes, Auxiliary parking areas, Pedestrian walkways, ATV trails and wheelchair access ways, Approaches to monuments, statues and fountains Golf cart path shoulders and aprons, Driveways, driveway shoulders and medians. Geoblock® Porous Pavement Fire Access Lane System Put to the Test [1994].

Additional Case Histories Project-specific design, construction and performance case histories for the Geoblock® system.

Palmer Hayflats Geoblock Porous Pavement System Application

The Geoblock® product was one of a variety of materials tested by the NPS and analyzed at a trail segment during the summer of 1999. Based on test results, 800 ft of Geoblock hardening trail was installed in 2000. Palmer AK Hay Flats Project

Cottonwood Creek Trail Head Geoblock Installation Palmer Hay Flats State Game Refuge 400 foot extension. Installed in 2013. Read full article here.

Online copy of "Managing Degraded Off-Highway Vehicle Trails in Wet, Unstable, and Sensitive Environments:" here.

Wrangell-St. Elias National Park and Preserve

Releases Plan To Repair ORV Trails

“This is totally awesome news with a big thank you to the Park Service. Finally, these ORV trails will be improved for local folks who use these trails for hunting, fishing, berry-picking, and access to their remote cabins,” said NPCA Alaska Sr. Regional Director Jim Stratton. “Another benefit of this plan is that the Wrangell-St. Elias hiking trail system will be expanded for all park visitors, creating new places to explore on foot while enjoying our country’s largest national park.”

Read The Full Article Here (PDF)

Tales from the

tundra (Kwigillinook, Alaska)

The Feb/March issue of Geosynthetics magazine features the article, Tales from the tundra,

The article highlights advantages of the GEOTERRA system that allowed it to meet the project criteria:

Can support all-terrain vehicles over soft & uneven ground

Allows vegetative growth through the open design

Provides support even when unfilled

The Denali Commission met Dec 12, 2007 to

review the Rural Road project nominations, including the

Hooper Bay nomination.

The Hooper Bay project was selected. The

Denali Commission will work with Federal Highway and NRCS

engineers to try to develop a

TRoad cook-book with ATV mini road (Troad)

standards accepted for construction projects and access to

federal highway funding to do so.

The Alaska NPS Rivers, Trails and Conservation Assistance Program helped to coordinate an ATV Trail Hardening Project with Sea Lion Corp in Hooper Bay Alaska. The NPS does not endorse other agencies or organizations, their views, products or services - Video, Picture & Links with Permission from NPS.

PDF Format:

https://www.geocheminc.com/pdf/0809tundra_atv_trail_proj.pdf

HOOPER BAY NEWS POD CAST:

Hooper Bay works to protect tundra from vehicle damage

![]() Trail helps heal

Alaska Native hunting grounds

Trail helps heal

Alaska Native hunting grounds

Read the Full Article:

Trails helps

heal Alaska Native Hunting Grounds

PDF Format:

https://www.geocheminc.com/pdf/Trail_Helps_Alaska.pdf

Bethel Geoblock Porous Pavement System Demo

Application

The Alaska NPS Rivers, Trails and Conservation Assistance Program helped to coordinate an ATV Trail Hardening Demonstration Project in Bethel. The NPS does not endorse other agencies or organizations, their views, products or services - Pictures with Permission from NPS.

Nome Alaska Geoblock Porous Pavement System Application Slideshow Presentation

Slideshow Pictures of a Geoblock Trail Hardening Stewart River Project North of Nome Alaska: https://www.geocheminc.com/suulutaaq.htm

White Mountains Geoblock Porous Pavement System Application

White Mountains National Recreation Area, Alaska: Quartz Creek Trail, White Mountains National Recreation Area, Alaska (WMNRA)

Flexible Structural

Bridge

The Geoblock®

system creates a flexible structural bridge within the topsoil layer,

promoting the vigorous growth of turf grass while protecting turf from the

harmful effects of vehicular and pedestrian traffic. The Geoblock® Porous Pavement System

is a series of interlocking blocks designed to offer turf protection and load

support in areas used by heavy vehicles. The blocks create a flexible

structural bridge system within the topsoil layer to support and distribute

concentrated loads.

Geoblock® Porous Pavement System

The Geoblock® system is comprised of

four major components:

1) The Geoblock® unit, 2) the

engineered base for support, 3) the selected topsoil infill, and 4) the selected

vegetation.

Both the Geoblock® unit and the base support soil work

together to support the imposed loading, while the Geoblock®

unit and the topsoil contribute to the vegetative support. Other

components may include a geosynthetic separation / reinforcement layer,

sub-drain components, and topsoil additives, which enhance vegetative

growth.

Click here for

GeoBlock component specifications and configuration examples.

Geoblock® & GeoPave System Usage Guideline

|

DESIGN GUIDELINE Depth of Engineered Base Recommendation: (Imperial) |

||||||||||

|

GEOBLOCK®5150 |

GEOBLOCK® |

GEOPAVE |

GEOPAVE |

|||||||

|

LOAD DESCRIPTION

TYPICAL

MAXIMUM

TIRE

GROSS VEHICLE LOADS |

VEGETATED SURFACES

Topsoil In fill & |

VEGETATED SURFACES

Topsoil Infill & |

AGGREGATE SURFACES |

VEGETATED SURFACES

Topsoil/Aggregate Infill & |

||||||

|

CBR1,2 2 – 4 |

CBR1 > 4 |

CBR1,2 2 – 4 |

CBR1 > 4 |

CBR1,2 2 – 4 |

CBR1 > 4 |

CBR1,2 2 – 4 |

CBR1 > 4 |

|||

|

HEAVY FIRE TRUCK & H-20 LOADING Typical 110 psi 80,000 lb |

6 in |

4 in |

14 in |

10 in |

6 in |

6 in |

Not

|

Not

|

||

|

Infrequent Passes |

Infrequent Passes |

Normal Traffic |

||||||||

|

Single axle loadings of 145 kN, tandem axle loadings of 220 kN. |

||||||||||

|

LIGHT FIRE TRUCK & H-15 LOADING Typical 85 psi 60,000 lb |

4 in |

2 in |

10 in |

6-10 in |

6 in |

4 in |

Not |

Not |

||

|

Infrequent Passes |

Infrequent Passes |

Normal Traffic |

||||||||

|

Single axle loadings of 110 kN. |

||||||||||

|

UTILITY & DELIVERY TRUCK & H-10 LOADING Typical 60 psi 40,000 lb |

2 in |

2 in |

6-10 in |

4-8 in |

4 in |

2 in |

4 in |

2 in |

||

|

Infrequent Passes |

Infrequent Passes |

Normal Traffic |

Infrequent Passes |

|||||||

|

Single axle loadings of 75 kN. |

||||||||||

|

CARS & PICK-UP TRUCK ACCESS Typical 45 psi 8,000 lb |

None |

None |

4-8 in |

2-4 in |

2 in |

None3 |

2 in |

None3 |

||

|

Occasional Passes |

Occasional Passes |

Normal Traffic |

Occasional Passes |

|||||||

|

Single axle loadings of 18 kN. |

||||||||||

|

TRAIL USE: SURFACE STABLIZATION <1,000 lb |

None |

None |

2-4 in |

0-2 in |

None |

None |

None |

None |

||

|

Loading for ATVs, golf carts, campers, boats, equestrian, motorcycle, bicycle, pedestrian, wheelchairs. |

||||||||||

|

1 CBR is the abbreviation for California Bearing Ratio. Methods for determining CBR vary from more sophisticated laboratory methods to simple field identification methods that use hand manipulation of the soil. If other-than-CBR soil strength values exist, use available correlation charts to relate the value to CBR. 2 For CBR <2, contact Presto Products Company for recommendations. 3 A minimum of 2 inches of aggregate base should be placed below the GeoPave units as a drainage layer and an infiltration storage area. Greater depth may be required depending upon design rainfall requirements and subbase permeability. ALL DESIGNS SHOULD BE CHECKED BY A CERTIFIED ENGINEER.

|

||||||||||

|

|

||||||||||

Recommended Topsoil:

Suitable topsoil should be pulverized prior to filling the Geoblock®

cells and contain sufficient organic content to support vegetative growth.

Topsoil such as sandy loam is recommended. Clay and clay loam materials are

considered unacceptable.

Recommended

Engineered Base: Vegetated Systems

A recommended ‘engineered base’ consisting of clear-stone /

crushed rock having an AASHTO #5 designation blended with topsoil will promote

vegetative growth and provide required structural support. The aggregate portion

shall have particles ranging in size from 9.5 to 25 mm (0.375 to 1.0 in) with a

D50 of 13 mm (0.5 in). The percentage void-space when compacted shall

be at least 30%. Topsoil, equal to but not greater than the aggregate void

percentage, shall be added and blended prior to placement. The mixture shall be

compacted to a density that will provide a minimum California Bearing Ratio of

7%. Under some conditions, a geotextile separation layer may be required between

the natural ground and the ‘engineered base’.

Recommended

Engineered Base: Non-Vegetated Systems

A recommended ‘engineered base’ for non-vegetated porous

pavement systems shall be a well-graded aggregate with a fines content less than

10%. The aggregate shall be compacted to a density that will produce a

California Bearing Ratio (CBR) of 7% minimum. After compaction, the surface

shall be uniform with no protrusions from larger aggregate particles.

[Contact Us!] for design assistance, specifications and/or technical field support and representation.

GeoCHEM offers assistance to anyone interested in evaluating, designing, building or purchasing a Geoblock® porous pavement system. You may access these services by [contacting us]. GeoCHEM reserves the right to withhold any information from any individual or company.

THE LINKS BELOW MAY REQUIRE ADOBE READER TO VIEW THEM. CLICK ON THE "GET ADOBE READER" BUTTON BELOW TO DOWNLOAD A FREE COPY IF NEEDED

Working with the

Environment

In many cities, current storm water

management systems are pushed beyond their capacities by run-off from

traditional hard surfaces. With over 87% open area at the surface, the Geoblock®

system offers a permeable solution. The Geoblock® design allows water to

percolate into the ground through drain holes in the bottom of the units,

decreasing storm water run-off and allowing natural groundwater replenishment.

Under rainfall simulation of 64 mm/hour (2.5 inches), the run-off coefficient

for the Geoblock® system is 1.5%. The Geoblock® units are manufactured from

up to 100% recycled polyethylene and are inert to common chemicals, will not

absorb moisture and are unaffected by freeze-thaw cycles.

Geoblock Technical Specifications

|

Geoblock® General Brochures/Case Histories |

|

|---|---|

|

An illustrative overview of the Geoblock porous pavement system. |

|

|

Project-specific design, construction and performance case histories for the Geoblock system. |

|

|

Geoblock® Design and Construction Tools |

||||||

|

Geoblock®5150 Design and Construction Overview |

A document tool containing the following design and construction information for the Geoblock system:

|

|||||

|

A comprehensive product specification in CSI-format based on the Presto Geoblock material specification. |

||||||

|

Presto Geosystems SPECMaker® ARCAT's SpecWizard Program Customized Geoblock® Specifications

|

|

|||||

Presto Geosystems Video Case Studies

Geoblock Porous Pavement System Case Studies

Geoblock®Fire Access Lanes

Geoblock Fire Access Case Study Summary (.pdf)

Fire Access Lanes / Pedestrian Green Areas

Friends University (.pdf)

Wichita, Kansas

SOKA University (.pdf)

Aliso Viejo, California

Green Parking

Phipps Conservatory Event Parking

(.pdf)

Pittsburgh, Pennsylvania

Jack Darling Park (.pdf)

Mississauga, Ont., Canada

Trails

Museum of Science and Industry Walking Trail

(.pdf)

Tampa, Florida

Walking Pathway (.pdf)

Caribbean Island

ATV/OHM Trail-Hardening

Hard Trails in Alaska Article

(.pdf)

Alaska

Palmer Hay Flats ATV Trail (.pdf)

Alaska

Aitkin and Itasca Counties Trail

(.pdf)

Aitkin & Itasca Counties, Minnesota

National Park Service, Managing Degraded Off-Highway

Vehicle Trails in Wet, Unstable, and Sensitive Environments Handbook

(.pdf)

Kodiak Island, Alaska

Trail Hardening Applications (.pdf)

Grass Steps

Edith Wharton's The Mount Grass Stairs

(.pdf)

Lenox, Massachusetts

Submit Geoblock

and/or Geoweb Project Information

The project information will be placed in our Project Library

as reference and will be considered for case studies and/or magazine editorials.

PRESTO GEOSYSTEMS FULL PRODUCT

LINE CARD: E-BROCHURE

CUSTOMER

LITERATURE REQUESTS